Dr. David Hackleman, Co-Founder and Managing Director

10 December 2019

Abstract:

Hemp oil was easily extracted from the Cherry Wine variety of Hemp grown in the mid- Willamette Valley of Oregon using the EssenEx®-100 and -300 extractor equipment from OilExTech, LLC. A preliminary assessment of effective operating conditions using the EssenEx®100 is as follows: For fresh cut hemp of water content ~25%, place 100g diced botanical in EssenEx®100. Extract using 1000W microwave for 6 minutes at full power, then rest 2 minutes (no power) and remove oil from hydrosol surface in usual manner. For low yielding hemp varieties, ~50g orange “zest” added to the botanical will induce greater yield and ease in oil layer recovery as long as orange oil in product is no issue.

Figure 1: 100% Hemp Oil from 50g fresh hemp, no Orange Zest used.

Figure 1 shows the recovered 100% Hemp oil as collected in the separation flask neck from the first 50g portion of Hemp sample number 2. Yield was 1.3% by mass as collected. (Equivalent to 1.5% “BDMi” yield). No orange zest was used nor necessary with this botanical sample.

Introduction:

Recently, Hemp once again is a viable, federally legal agricultural productii in the United States. This enabled OilExTech, LLCiii legal freedom to study extraction of hemp oil. In the family Cannabaceae, Hemp is a member of the genera Cannabis (hemp, marijuana) with a close relative the genera Humulus (hops). The Essential oils of these plants share many common components, but in differing quantities. OilExTech, LLC has previously studied Hops oil extractions and found satisfactory operating conditions in the EssenEx®100 and 300 series of reactorsiv. No work on marijuana has taken place due to its current federal legal status. The extractable essential oils from Hemp are located primarily in the buds and leaves rather than the stems and other plant components.

Figure 2: From Köhler’s Medizinal-Pflanzenv

Figure 2 shows the components of the Hemp Plant. The buds are the fruiting bodies predominantly at the top of the stems. It is appropriate to note that Hemp Essential Oil is not the same as Hemp Seed Oil. Mechanical pressing of the seeds delivers the seed oil, while extraction such as via the EssenEx® devices, Steam Distillation, and supercritical CO2 extraction yields the essential oils.

A local agricultural concern graciously supplied a Hemp sample for this study. Essential oil content in Hemp, like most other botanicals is a function of maturity as well as sub- species. The literature on Hemp while not fully explored prior to the experiments in this report, suggests a wide range of essential oil content in varieties of Hemp from as low as nearly undetectable to nearly 1% by mass in select hybrid varieties. The best practice of presenting oil yields as “% by mass of BDM”vi is in use. Based on the sample size, it was possible to identify an extraction process, however not to optimize the yield. This study also identified qualitative information on the physical properties of the oil.

Experimental:

OilExTech obtained two independent Hemp samples of 0.5 to 1Kg, and then divided each into smaller portions to study in a variety of operational conditions. The equipment used for experimental studies is detailed in Appendix “B”.

Sample 1: OilExTech received the first (c.a. 500g) sample in a polyethylene bag and the second (c.a. 800g) in a polyethylene bin. Both were stored at room temperature (c.a. 70F –convert to C) at the OilExTech Manufacturing Facility in Lewisburg, OR. OilExTech divided the first sample into five portions of roughly 100g each (Table 1)

Table 1- First Hemp Sample

Next, we split sub-samples into two smaller samples of roughly 50 grams each and prepared them for specific experiment conditions as described in Table 2 below. The Experiment numbers outline each sample’s pedigree! A Key to understanding the Experiment number is in a note at the end of this reportvii. The mass of Hemp is as picked, not BDM (Bone Dry Mass). Hence, we corrected yields to that standard conditionviii. The solvent “O zest” is the zest of standard Naval Oranges. “Prep” “add” means the solvent was added to the Hemp. 24H means that after adding and mixing, the mixture rested 24 hours to allow the solvent to diffuse into the Hemp. The only two solvents in use were water and orange zest.

Table 2 First Hemp Sample

Notes for each Experiment in Table 2:

1. Strong odor but ran too long (error), melted ice knob and screw.

2. Strong odor, ice collection beaker overfilled, lost oil.

3. 2 days before run after hydration led to congealed hemp sample.

4. Observed bubbles of hemp oil rising to surface, could not collect.

5. Sheen on surface, decided to run a second time

6. Ice fell into collection beaker. Generally, any hemp oil was lost.

7. No microwave excitation, only addition of solvent and absorption time.

8. First use of Orange Zest, yield good. (25 gram hemp sample)

9. Second Orange Zest, yield similar to 8 (25 gram hemp sample)

10. Some ice fell 2 min into run, likely lost some oil but still good yield. For total oil

yield, add to 12’s results.

11. Ice did not fall, for total add to 13’s results.

12. Added 10ml water → additional oil but ice fell. 10+12 hemp + orange = 1.3%

13. Rerun of 11, hence total yield on this hemp + orange = 0.9%

14. Added more zest – checking for optima

15. Added less zest – checking for optima

16. Added 10ml water and did not see additional oil

17. Same as 16.

Conclusions from Sample 1 study:

1. Apparently, this sample of Hemp did not have a particularly high hemp oil content. Many varieties of Hemp do not. The range expected from Hemp varieties varies from almost undetectable to ~1% by mass (BDM) at present, and research is underway toward increasing the oil content. Variance of growing conditions, maturity and harvest methods greatly influence oil content.

2. For very low oil content Hemp samples, the use of orange zest (a source of limonene) affords an effective co-solvent extraction of the essential oils in Hemp. As essential oil extracted in this manner will now contain significant quantities of limonene, any use of the so extracted oil will include the properties of this material. While proven beneficial in many applications, the researcher should confirm any additive such as this to be acceptable in their specific application.

3. After extraction, the Hemp fiber samples were adequately dry for long-term storage or use in other applications.

Sample 2: A local Hemp farm kindly provided the second sample, obtained nearly fresh during fall harvest 2019 and stored at OilExTech in a clear plastic 30-quart storage tote. Water content measurement took placex. The estimate is 22%. Aliquots taken directly from the bin performed the experimental runs as described in Experiment Table 3 below. This sample needed no Orange zest. An EssenEx®-100A performed all experiments except 29 & 30 which utilized an EssenEx®-300.

Table 3 Cherry Wine Hemp

Notes for each experiment in Table 3:

18. Extractor left in MW 2 minutes after excitation ceased.

19. Sample was Buds only, beaker very hot, ice might have fallen.

20. Second run of sample 2-2 The total sample 2 yield is therefore 1.1%

21. First run of Sample 2-3

22. Second run of sample of 2-3

23. Total yield (combined) of run 22 & 23 is yield of sample 2-3 → 0.9% 24. Sample 2-4 first run

25. Sample 2-5 first run

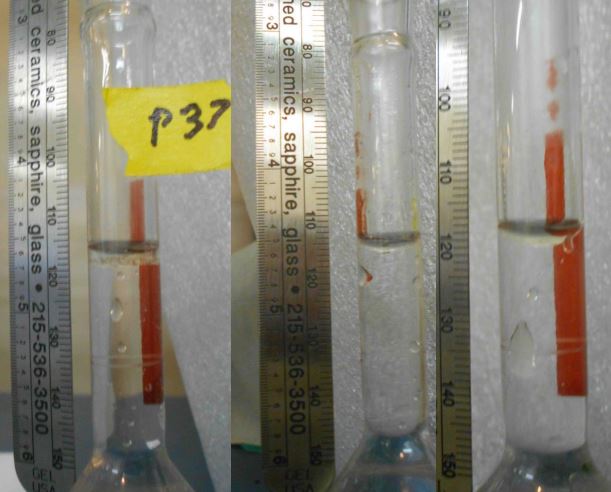

26. Combining samples 2-4 and 2-5 and then re-run together. Total yield is the average of the 24+26 and 25+26 weighted by mass of each, ~ 0.7 to 1.0% 27. Sample 2-6A first run in EssenEx-100, oil adhered to inside of flask, could notmeasure yield! (See Photo – Appendix C.)

28. Sample 2-6B same effect as in 27 above.

29. Sample 2-6 was recombined and run in Essenx-300 in a larger MW oven

30. Ice remained hence continued run an additional 300 seconds

Last number is the yield of the combined runs on Sample 6, 0.6% not counting the oil that adhered to inside of flasksxii. Subsequent to these studies, samples of oil and hydrosol were submitted for GC analysis.

Conclusions:

• These experiments provided qualitative and semi-quantitative information regarding the effect of source, portion of plant, power density, time, and added solvents on the overall oil yield.

• They confirm that Hemp Oil may be extracted using the EssenEx® reactors.

• They do not offer an optimum extraction process as a larger sample of Hemp is needed to accomplish that goal, however two conditions were found that generally offer efficient extraction:

o 50 – 100 g Hemp in EssenEx®-100,

▪ If dry, add water ~ 1⁄2 mass of Hemp but no more than 40g.

▪ Full Power, 360 seconds, 2 minute “cool down” undisturbed in Microwave oven. o If Hemp low oil yield, add 25g Orange Zest, same conditions.

• The Hemp oil content varies greatly from sample to sample

• The oil has a strong tendency to adhere to glassware, can reduce the amount actually obtained after extraction. Remedy is to clean glassware carefully.

• A secondary product: Hemp oil hydrosol is quite aromatic and produced in abundance by this method.

Appendix A: Method of measurement of water content: (Also on the OilExTech Website in Scientific Research with the above title).

Reporting of results from essential oil extraction of botanicals is best compared between researchers if one standardizes on the water content in the botanical as that variable will directly influence the oil yields reported in %/mass (“per-cent by mass of sample”). Generally, the researchers will determine the water content of the botanical and then convert the specific measurements obtained to the equivalent percentage by mass that would exist were the sample without the inclusion of water. The terminology is the %/mass BDM (per-cent by mass of “bone dry material”). This reporting technique is common in the agricultural sciences.

While tools exist and are readily available to perform this function. A Search for “Moisture Analyzers” will offer many results. An example is Mettler/Toledo HE-53 Halogen source moisture analyzer. It is capable of 0.15% accuracy with a 2g sample and 0.05% with a 10g sample. Unfortunately, these rather specialized devices are also expensive. The HE-53 has a list price of $2,800 at this time. One can purchase lower cost, less robust units for $350 or higher, however unless one has a lab doing a large number of studies, a simple option using a balance, thermocouple/reader and oven will suffice and will be described. This method, using any balance capable of 0.01g precision and a capacity of 25 grams is capable of precision and accuracy of 0.05%. Balances of this nature are very inexpensive at this time (<$10.00). Access is required to a standard kitchen oven and optionally a thermocouple temperature-measuring tool.

The procedure:

a. Obtain a botanical sample of ~25 g. (Multiple samples preferred, one is

adequate.)

b. Obtain a piece of aluminum foil of adequate size to contain botanical sample.

c. Fashion foil into a tray for each botanical sample with which to hold the sample

and transport it to/from the balance and the oven. Use gloves to retain purity.

d. Weigh the tray(s) without botanical for the “tare weight”.

e. Set the Oven at 250F (~120C)

f. (Optional) – place thermocouple in oven and reading tool adjacent.

g. Make initial weighing of each sample in its tray and record as “as obtained”.

h. Place samples in oven for 30 minutes

i. Remove from oven and weigh each sample

j. Record the weights (as well as the oven temperature from optional

thermocouple) and the time to the nearest minute.

k. If weights are the same as measured the previous time, you are finished, go to “m.” below.

a. If only 0.1% reproducibility is wished, mass of same sample need be only

within +/- 0.02g of previous measurement.

i. Similarly, you can calculate for other reproducibility levels.

l. If weight not yet stabilized, return to “h” above and repeat process.

m. Calculate the total weight loss of each sample in grams and divide by initial mass of sample. Record as % by mass water in sample.

a. Use the following equation to adjust all masses of oils obtained in

extractions of this particular botanical and report them as % BDM.

% BDM = (% measured * 100) / (100 – % by mass water)

Results for this specific experimental set:

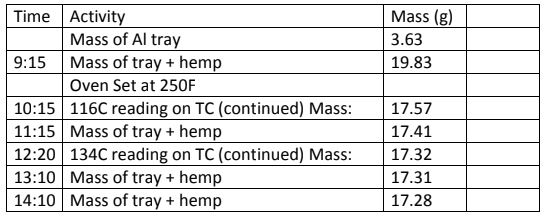

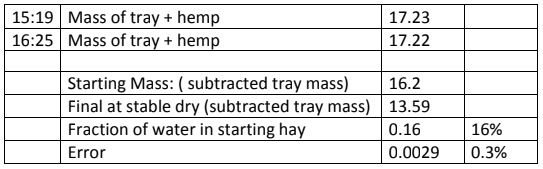

Time Activity Mass (g)

Mass of Al tray 3.63 9:15 Mass of tray + hemp 19.83

Oven Set at 250F 10:15 116C reading on TC (continued) Mass: 17.57 11:15 Mass of tray + hemp 17.41 12:20 134C reading on TC (continued) Mass: 17.32 13:10 Mass of tray + hemp 17.31 14:10 Mass of tray + hemp 17.28

15:19 Mass of tray + hemp 17.23 16:25 Mass of tray + hemp 17.22

Starting Mass: ( subtracted tray mass) 16.2 Final at stable dry (subtracted tray mass) 13.59 Fraction of water in starting hay 0.16 16% Error 0.0029 0.3%

Appendix B: Equipment used:

EssenExTM-100A Essential Oil Extractor system (www.oilextech.com ) EssenExTM-300 Essential Oil Extractor system (www.oilextech.com ) MyWeigh®-iBalance i3000 Analytical Balance. (3100 +/- 0.01g capacity) Fluke® 574 IR/contact Thermometer Panasonic® NN-SA651S Household Microwave oven (1.2 cu Ft, inverter-style, 1100W) LG® KCRT2919ST Countertop Microwave oven (2 cu Ft, 10” opening height, 1200W) Nikon CoolPix L32 digital camera Standard machinist’s steel rule (mm/decimal inches)

Appendix C: Photos of oil sticking to glassware:

Figure 3 Oil Stuck on Glass

With kindest regards,

Dr. David Hackleman

Managing Director; OilExTech, LLC

iBDM = Bone Dry Mass. Computed by determining the water content of the botanical (see appendix A).

iihttps://en.wikipedia.org/wiki/Hemp_Farming_Act_of_2018

ivVisit https://oilextech.com/engineering/scientific-research/ — Hop Oil Extraction

v Wikipedia public domain image: https://en.wikipedia.org/wiki/Cannabis_flower_essential_oil File:Cannabis_sativa_-_Köhler–s_Medizinal-Pflanzen-026.jpg

vi BDM = Bone Dry Material. By providing % by mass of BDM, the reader can compute the equivalent expected yield for any particular hemp sample by compensating for its particular water content.

vii Sample key: If sample 1-1Ar existed, the first “1” signifies that it is from large sample 1, the “-1” means it is the first sub- sample from that large sample, the “A” is the first sub sample of that sub-sample. “AB” and “45” means two sub-samples recombined. The lower case “r”, means the event is a re-run of the same material. A re-run means the material has been previously extracted hence usually one expects very little additional essential oil in the material. Similarly, “p” means a preparation instead of a microwave excitation. After the lower case letter, a “+” means that after inspecting the material, it was replaced in the microwave and excitation was continued at the time and power mentioned.

viii See note about method to measure water content, Appendix “A”.

ix As an example, see this article: Vuerich, Marco & Ferfuia, Claudio & Zuliani, Fabio & Piani, Barbara & Sepulcri, Angela & Baldini, Mario. (2019). Yield and Quality of Essential Oils in Hemp Varieties in Different Environments. Agronomy. 9. 356. 10.3390/agronomy9070356.

x Water content measured by taking a small (apx 20gm) sample and repeatedly weighing sample during drying at 115-135C. See Appendix “A”.

xi The EssenEx®-300 has roughly 3 times the botanical volume capacity of the EssenExTM-100 series, however requires a microwave oven with a minimum vertical clearance of 9.5 inches (24 cm).

xii See Photo in Appendix “C”

xiii Data has not been forthcoming at this writing. It will be appended when supplied. Qualitative results expressed indicate that a xylene extract from the Hemp Oil hydrosol yielded trace quantities of Hemp Oil by GC/MS as expected. (1/8/2020, email communication to D. Hackleman).

xiv An example is Mettler/Toledo HE-53 Halogen source moisture analyzer.